Examples of countermeasures in the semiconductor and LCD industry

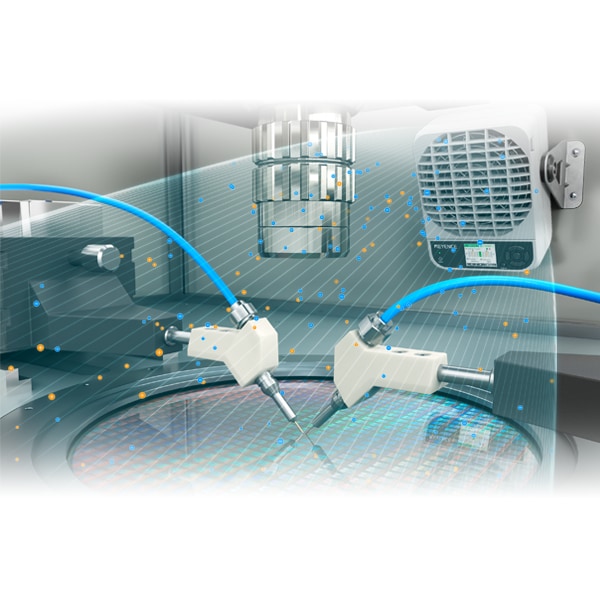

Preventing static electricity during wafer testing

- Electrostatic destruction

Reliable static elimination is possible in wafer testing environments by installing a feedback sensor near the target to enable constant monitoring of the target area.

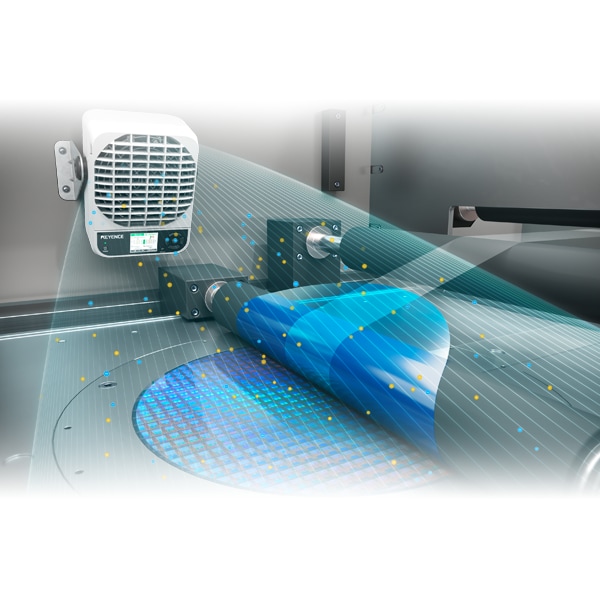

Eliminating static when peeling protective film from wafers

- Electrostatic destruction

- Adhesion of foreign particles

Static electricity can be eliminated quickly over a wide area. Recording static elimination results during peeling makes it possible to identify the cause of problems.

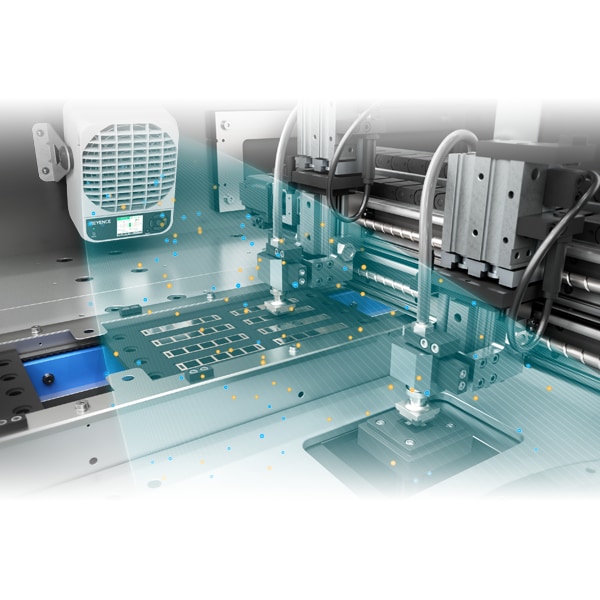

Static electricity prevention during die bonding

- Electrostatic destruction

Using high-speed static elimination to prevent discharges during die releasing helps reduce maintenance that would otherwise be necessary with conventional devices.

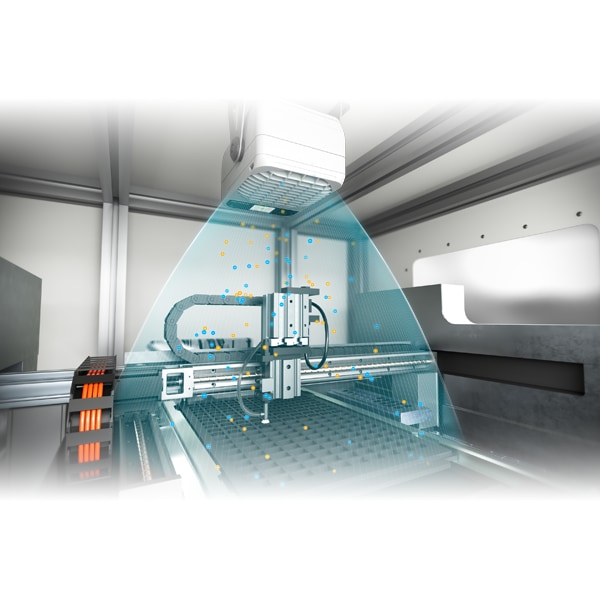

Test handler ESD protection and quality assurance

- Electrostatic destruction

With a high-performance ion balance of ±1 V, the device can be used safely in any semiconductor manufacturing site. Previous static elimination results can also be checked to identify affected periods in the event of a problem.

Static elimination during fork transferring of liquid crystal glass

- Adhesion of foreign particles

Airless and energy-saving ionizers help reduce air consumption in a factory while ensuring advanced static elimination performance.

Static elimination during air showers

- Adhesion of foreign particles

Installing ionizers in air shower rooms—where the risk of introducing foreign particles into a clean room is highest—helps improve dust removal effectiveness.

For more information, please contact KEYENCE.