Laser Marking Systems / Laser Markers

Laser Marking

Laser marking can be used for marking or processing various types of materials. There are also several different marking and processing methods. Due to the varying capabilities and features of laser marking technologies, this inherently leads to many different applications.

However, the appropriate laser marking system and peripheral equipment vary depending on the material and desired marking or processing method. The laser light being used can also vary. This section introduces the basic knowledge required for performing laser marking.

What is Laser Marking?

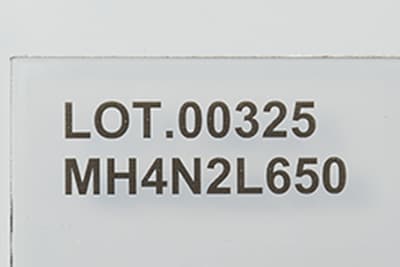

Laser marking is a marking method that uses a focused laser beam to alter the surface of a target. The laser beam is emitted by an oscillator and scanned using a mirror (known as a scanning mirror), and a focusing lens is then used to focus the beam on the target and mark it by altering the surface. Because laser marking involves using light to change the target surface, this method is more resistant to abrasion than ink-based marking, and the marking does not fade over time.

We’re here to provide you with more details.

Reach out today!

Industry-Specific Applications of Laser Marking Technologies

The list of industry-specific applications where marking lasers are used is growing year by year. Some of these include:

This brief list of examples doesn’t scratch the surface of where laser marking systems are used. Nevertheless, the points above show how diverse the technology’s applications can be. Because laser markers can work with many materials, it’s easy to see why the technology is relevant to almost any product. While alternative methods have been able to accomplish some impressive feats in manufacturing, the world is demanding change.

From production quality to traceability, consumer satisfaction, laws, and regulations, manufacturers are being forced to adapt to changing times. This is for the better in more ways than one, as learning how laser marking works will lead to better efficiency, cost savings, employee satisfaction, consumer retention, and more.

Discover more about this product.

Click here to book your demo.

Laser Marking on Metal

Laser marking can be performed on metal through black-annealed marking, where the laser causes oxidation; white marking, where the laser is used to scrape away the target surface; and engraving, where the laser is used to carve deep into the target surface. Each method is used for a specific purpose. This section explains the characteristics of each method, providing additional insight into how laser marking works from several angles.

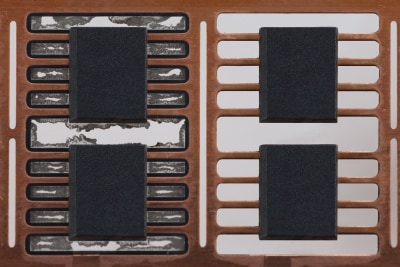

Black-annealed (oxidation) Marking

When the laser beam is applied to the marking target, the focus is shifted so that only the heat will be conducted. Applying heat without engraving the target forms an oxide film on the surface. This film appears black and represents black marking.

White Etching Marking

The laser beam is applied to the marking target at the focal point. The metal surface is slightly removed to expose an uneven surface. This causes irregular reflection of light to create markings that appear white.

Engraving Marking

Laser light irradiates the focal point and etches the surface of the target for marking. A deeply engraved impression can be made by increasing the amount of engraving by increasing the laser irradiation count.

Curious about our pricing?

Click here to find out more.

Metal Marking Machine

3-Axis Hybrid Laser Marker MD-X Series

The 3-Axis Hybrid Laser Marker MD-X Series combines the strengths of a conventional fibre laser with those of a YVO4 system. Fibre lasers are designed for long service life and high output power for high speed marking and deep engraving applications. YVO4 lasers are designed for high quality, delicate marking and increased depth of focus for flexibility. Together, these lasers create the MD-X with high peak power and a short pulse laser.

Combining these 2 marking methods creates a laser that is powerful enough to meet stringent cycle time requirements, but also robust enough to achieve quality markings on any metal. Paired with KEYENCE's 3-Axis control, full field auto-focus, and automatic position adjustment, the MD-X Series is ideal for any metal marking need.

Get detailed information on our products by downloading our catalogue.

View Catalogue

Laser Marking on Plastic

There are three patterns for marking on plastic using a laser: Foaming, where the laser causes bubbling; chemical change, where the laser reacts with the pigments in the plastic; and carbonisation, in which a high-energy laser is applied to the target surface.

Foaming

When the base material is irradiated with a laser, bubbles are generated inside the material. These bubbles are sealed under the surface layer of the base material, causing them to appear white. Foaming is more visible on darker base materials.

Chemical Change

As the laser light reacts with the metal ions in the base material pigment, a chemical change occurs, resulting in colour development. The appearance varies depending on the colour and material of the target.

Carbonisation

When high energy is continuously applied to an area, macromolecules of the element around the base material are carbonised and turn black. The polycarbonate material shown above is transparent but produces a beautiful black colour when carbonised.

Laser Marking on Other Materials

Laser marking can also be used for marking materials other than metal and plastic. For example, in addition to ceramic, paper, and wood, laser marking can be used on various transparent and translucent targets. Laser marking can also be used on targets with a surface coating that can be peeled off to reveal the underlying base material or painted surface.

Coated parts

Paper

Wood

Ceramic

Discover more about this product.

Click here to book your demo.

Processing with a Laser Marking Machine

Cutting

During cutting, the laser light is scanned to the specified location to cut the desired shape. In addition to easily cutting complicated shapes, this process can also be used for removing gates and burrs or other purposes.

Surface Reformation

In this process, the laser light is used to remove a target’s surface material, such as paint, film, or plating. Surface reformation also changes the wettability of the surface material to increase the bonding strength and prevent any paste from flowing out.

Drilling

Laser-based drilling uses laser light to irradiate a single point of a target to drill a hole through melting and evaporation. Controlling such factors as the size and power of the laser light makes it possible to drill holes as necessary for the application.

We’re here to provide you with more details.

Reach out today!

How to Use a Laser Marking Machine

Laser marking requires not only a laser marking machine but also a device for setting the marking target in the correct position. Laser marking machines are available as stand-alone systems, where targets are set and marked one at a time; indexing systems, where several targets are positioned separately for marking; and inline systems, where targets are marked during transportation. This section introduces the features and applications of each system type.

Stand-alone Systems

With a stand-alone laser marking system, targets are placed one at a time on the stage for marking. This type of system is best for use with targets of various sizes and shapes requiring frequent tooling changes such as height adjustment. System specifications can be customised to include automatic stage lifting/lowering and foot switches for starting marking.

Precision jack

Manual vertical adjustment is possible. Equally spaced screw holes allow jigs to be easily mounted.

Interlock

The safety switch prevents accidental laser emission. Lasers won't emit while the door is open.

Interior lighting

The bright lighting in the laser box allows the user to comfortably position the target and check the marking.

Light-blocking panel

The panel blocks the laser beam. The user can check safely even while the laser is activated.

Dust collector

The dust collector is optimised for collecting dust produced from marking.

Various operation buttons

Frequently used buttons such as the Start Marking button are mounted. Also, a table for a PC or a touch panel can be attached.

Indexing Systems

Indexing systems include a positioning device that moves targets placed on a turntable to the marking position. With this type of system, marking can be performed toward the back while targets are being placed toward the front, allowing for shorter cycle times than stand-alone systems.

Inline Systems

Inline systems are suited for marking while a target is being transported along a production line. In certain situations, marking is possible without stopping the target, but other situations require the target to be stopped. The ability for inline systems to mark targets on a production line makes them indispensable for mass production.

Curious about our pricing?

Click here to find out more.

Laser Marking Machine Types and Features

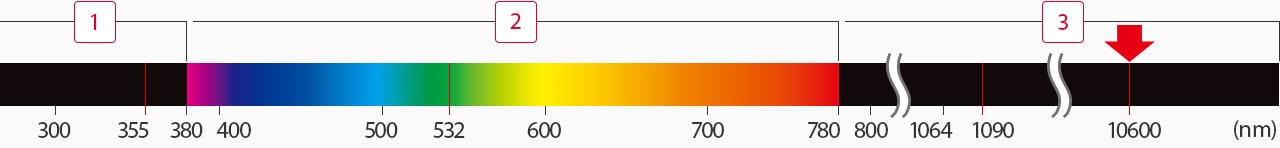

There are various types of laser marking machines available, each with different laser wavelengths, and each best suited for different materials and applications. This section introduces the features and applications of the typical types of laser marking machines: fibre laser marking machine, UV laser marking machines, and CO2 laser marking machines.

Fibre Laser Marking

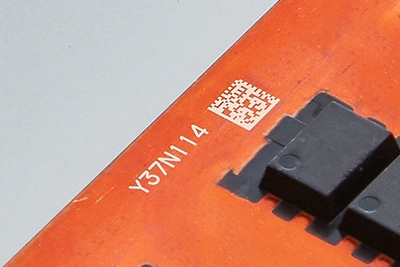

Fibre laser marking machines have a 1090 nm wavelength, making them IR (infrared) lasers. Fibre lasers can mark a wide range of materials, though they are optimised for metal marking applications. Their high power makes them perfect for annealing and engraving applications, but they cannot mark transparent objects since IR light passes straight through.

-

1Ultraviolet range

-

2Visible range

-

3Infrared range

Light wavelength distribution map

Engraving (painting after marking)

Vehicle body frame

Black-annealed Marking

Bearing

High-speed 2D Code Marking

Engine block

Etching

Key cylinder

Laser Cutting

Aluminium board

Burr Removal (frame IC)

Left: Before processing, Right: Burr removed

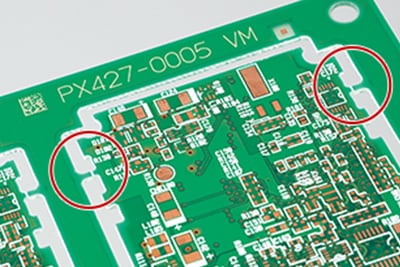

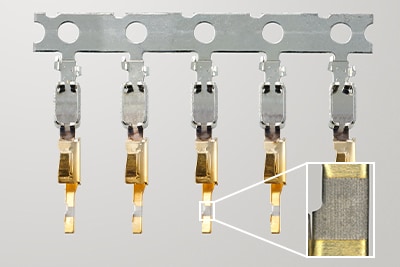

UV Laser Marking

UV lasers use a highly absorptive wavelength (355 nm) to mark parts. This high absorption rate allows UV lasers to perform "cold marking," ensuring that no extra heat stress is applied to materials, including those with high reflectance such as gold, silver, and copper. This minimises soot and burrs caused from typical marking and processing.

-

1Ultraviolet range

-

2Visible range

-

3Infrared range

Light wavelength distribution map

Multicolour automotive relays

Earbuds

Chemical bottles

Copper lead frames

Steel tools (scissors, etc.)

Food packaging film

CO2 Laser Marking

CO2 laser marking machines have 10x the wavelength of standard wavelength systems. They're great at marking paper, resins, wood, rubber and transparent materials (like glass and PET). However, it's nearly impossible to mark metal with a CO2 laser marking machine because the laser light is not absorbed.

-

1Ultraviolet range

-

2Visible range

-

3Infrared range

Light wavelength distribution map

Cartons

Bottles

Design marking

Glass wafers

Weatherstripping

Electronic PCBs

We’re here to provide you with more details.

Reach out today!

Selecting a Laser Marking System

Sorting through the different types of laser marking designs can seem convoluted if you're new to the technology. However, their differences can be broken down into a few key areas. Regarding the right laser system for your business, several specific focal points are considered that will help you align the right laser with your organisation's needs.

Here are a few important areas to focus on:

- The types of materials the laser can work with

- Any necessary safety considerations

- The types of laser marking systems being used

- The specific laser marking applications that you have planned

All of these points are bound to vary to some degree depending on the kind of laser marking process you need to work with. Whether you're laser marking on metal or soft wood, some laser marking systems are better for some materials than others. The same can be said about how these systems mark materials.

Whereas metals can take on more force, effective marking on a soft wood may require a gentler approach. Some of this considers the type of marking you're working with, but you would also be surprised at how adaptable these technologies really are. Regardless of whether it is different types of laser engravers or markers or simply learning the ins and outs of the tech itself, you want to speak with experts on the matter.

Discover more about this product.

Click here to book your demo.

Why Choose KEYENCE for Laser Marking?

You'll find that working with us at KEYENCE goes far beyond our laser marking technologies. How does laser marking work? We can guide you through this question in detail and offer the long term support you need to integrate and evolve your manufacturing processes.

Although we have years of experience navigating these industries, the strong benefit behind working with us comes from our proven expertise. You won't find any cut corners in our designs, which not only contest alternative methods but are leading the way for laser marking applications in the future. Contact us today to learn more about how we can help you transform your production and laser marking methods.

We’re here to provide you with more details.

Reach out today!

Laser Marking Videos

These videos show laser marking on various materials and products. Learn about the different finishes created with each application and the takt time required for marking.

ML-Z Radiator

Watch a KEYENCE ML-Z laser mark a radiator.

We’re here to provide you with more details.

Reach out today!